DSMax 3D Laser Displacement Sensor Features

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers:

- High scan rates (up to 18 kHz) at full measurement range

- Maximum resolution images (2,000 profile points)

- Fast high dynamic range (HDR) image

These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

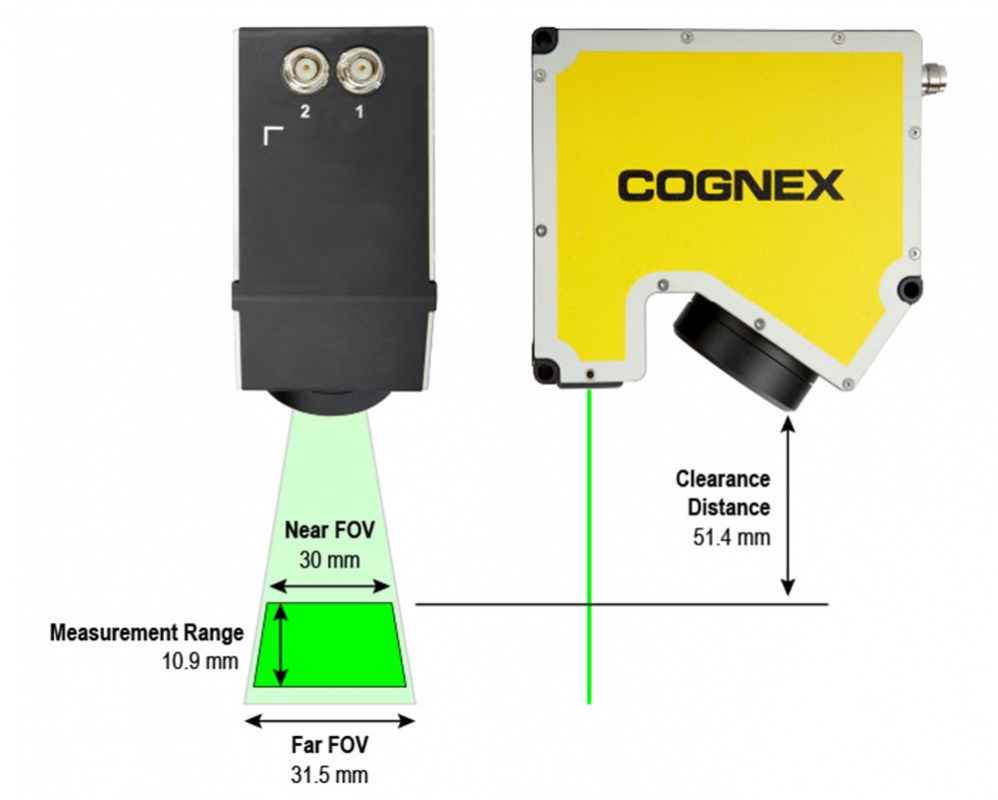

Accurate 3D inspections of small, detailed parts

DSMax concentrates 2,000 profile points within just a 31-mm field of view (FOV). The higher the number of profile points spread across a field of view reveals more details about the part and increases the precision of the 3D image allowing for more accurate 3D inspections.

.jpg)

Short cycle times increase throughput

DSMax acquires high resolution 3D images 5 times faster than other displacement sensors on the market. DSMax uses a high-speed imager, high-speed compressive sensing technology, and the CoaXPress® protocol to achieve up to 18 kHz (full field) scan rates at maximum resolution that reduce cycles times and maximize throughput.

.jpg)

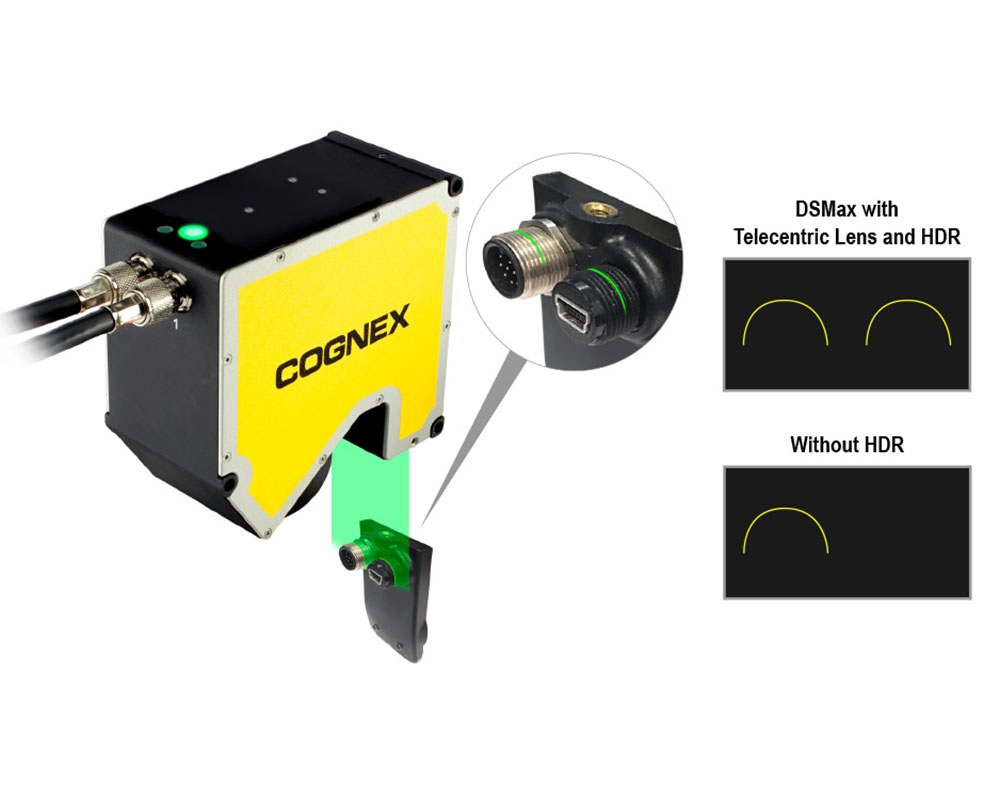

Telecentric optics optimize image formation

DSMax is equipped with a telecentric lens which reduces shadows and delivers high-contrast images. It achieves this by directing the laser line straight down on the object reducing the amount of light reflected away from the lens and increasing the light reflected back to the imager. Telecentric optics are ideal for precise measurements, where accuracy, repeatability, and throughput are necessary to solve the application.

.jpg)

Fast High Dynamic Range (HDR) improves image acquisition

DSMax acquires images with fast HDR reducing noise in the image and improving accuracy. HDR prevents DSMax from being affected by bright or highly reflective features on the part, delivering an optimized image for machine vision inspection.

.jpg)

.jpg)