In-Sight Laser Profiler Features

The In-Sight laser profiler is a measurement system used to verify dimensionality for gauging, inspection, and ID applications. The In-Sight laser profiler is configured using the In-Sight EasyBuilder user interface. This intuitive, easy-to-use software makes it simple for manufacturing and quality engineers to develop, deploy, and support accurate and reliable measurements on the factory floor.

Set up and deploy in 4 easy steps

- Acquire Profile—With a click of a button, profile optimization technology renders the most accurate outline of your part.

- Locate Object—Sophisticated object detection technology minimizes the need for costly fixturing and ensures measurements are performed in the correct location.

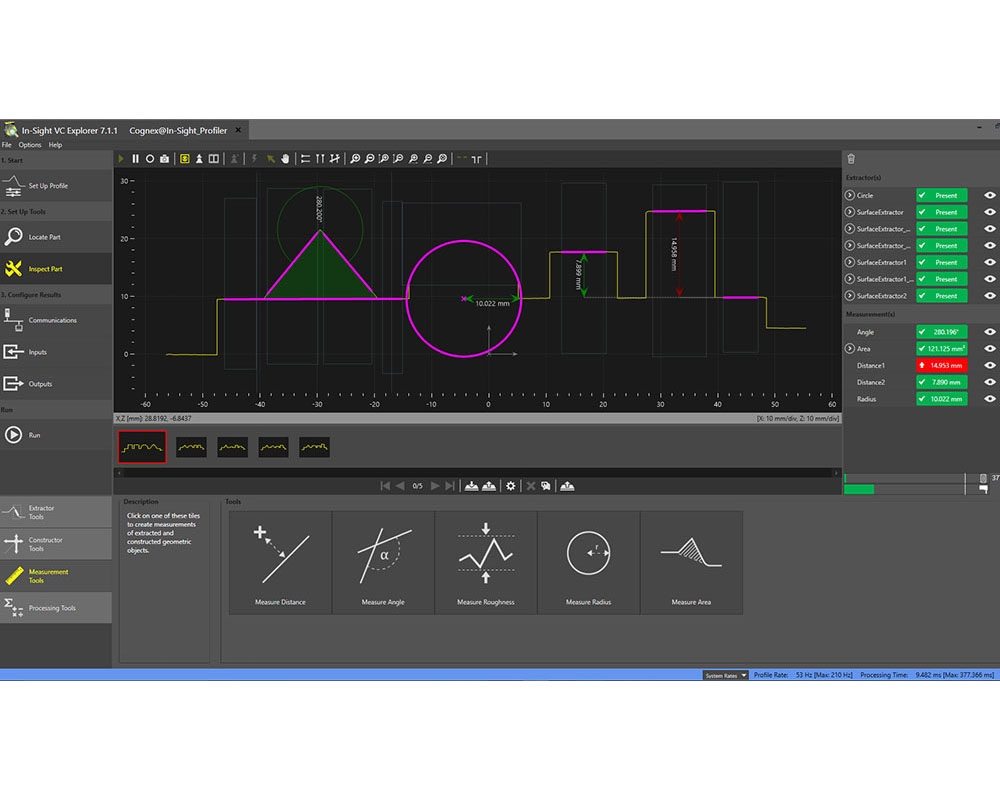

- Measure—Flexible In-Sight laser profiler toolset extracts features, constructs reference points, counts key features, and verifies whether a product has been manufactured within tolerance.

- Communicate Results—Measurements are sent to a PLC or an overall pass/fail is sent directly to a discrete output. Profiles and measurements can be stored on a controller for downstream analysis or quality control logging.

Monitor production line activity from anywhere on the factory floor

The In-Sight laser profiler offers mobile, platform-independent visualization for accessing HMIs (human machine interfaces) from anywhere on the network. An HTML-based user interface allows users to monitor production line activity from any laptop, tablet, smart phone or other mobile device.

Trusted technology for reliable, repeatable results

The In-Sight laser profiler system combines Cognex displacement sensor heads with the In-Sight VC200 vision controller. Using industry-leading algorithms, the system extracts the profile, performs highly accurate measurements and analyses the results. Advanced vision tools provide an accurate surface location even if the surface has defects.

.jpg)