Calibrated 3D Vision from Cognex

Cognex 3D displacement sensors optimize product quality by providing three-dimensional inspection of your products. The sensors are factory calibrated and include industry-leading Cognex machine vision software with powerful 2D and 3D toolsets and a compact, IP65-rated design that withstands even the harshest factory environments. Combined with unique field calibration technology Cognex 3D vision provides the highest accuracy data despite mechanical mounting or motion errors, as well as enabling the simultaneous use of multiple sensors on wide production lines to generate single high resolution 3D images.

Benefits

Complete 2D and 3D machine vision solution

-

Expanded range of sensor options

-

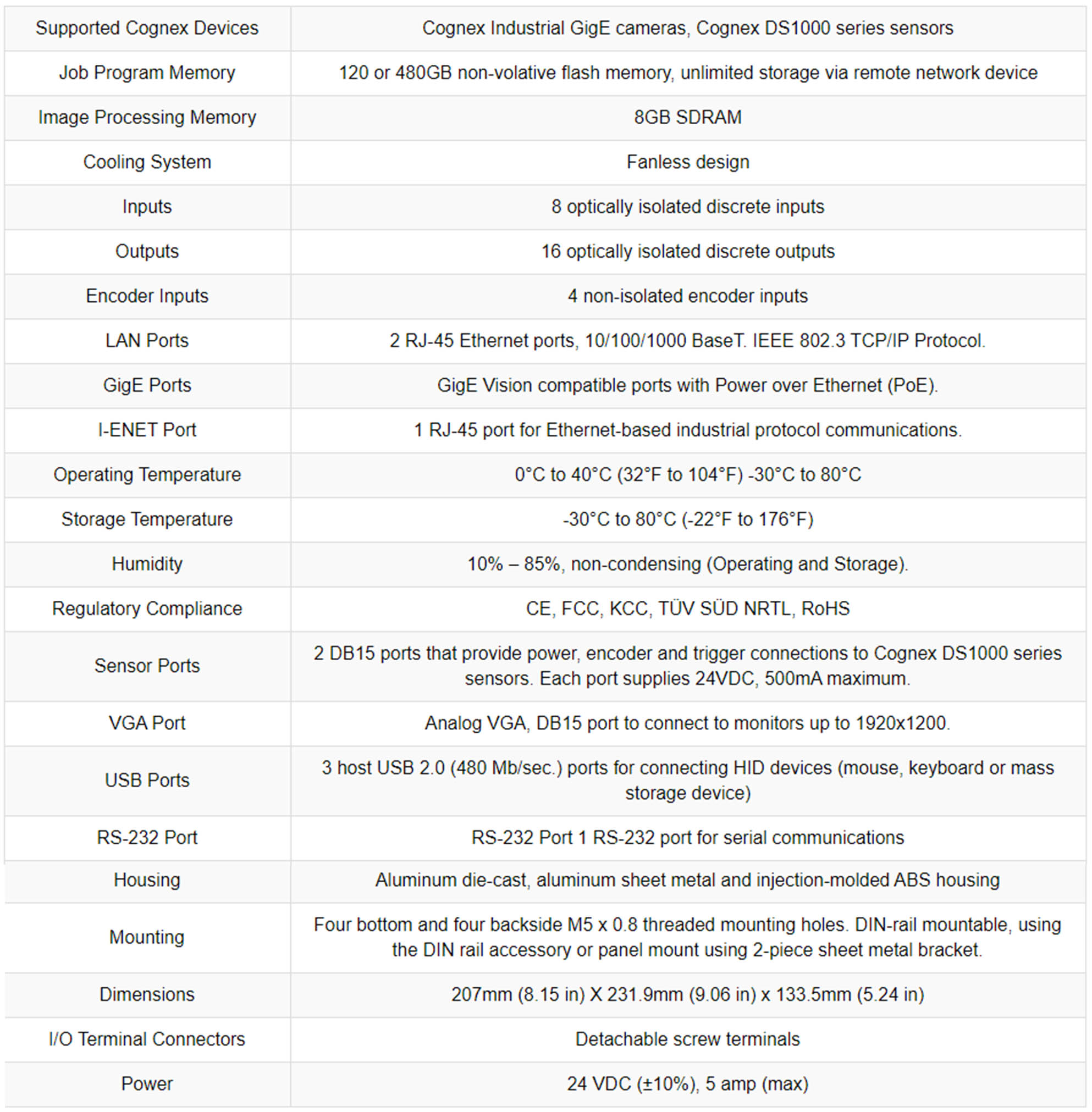

Bundled with VC5 Controller

-

Easy deployment with Cognex Designer™ software

Measurements provided in real-world units

-

Calibrated 3D system

-

Micron-level accuracy

Easy-to-use field calibration

-

Protection against misalignment and motion errors

-

Consistent results across production lines

3D image stitching

-

Higher resolution and wider fields of view

-

Simplified multi-head analysis

Contrast independent inspection

-

Dark object on dark background

-

Independent of color

Concurrent intensity data

-

Spatially-aligned 3D and 2D vision

-

Enhanced textured 3D visualization

Ability to combine 3D sensors and 2D cameras

-

Many applications require both

World-class 3D and 2D vision tools

-

Height, volume, plane fitting and tilt tools

-

PatMax®, IDMax® and OCRMax™ algorithms

Industrial IP65 housing

-

IP69K enclosure option for food and beverage applications

Fast scan rates

-

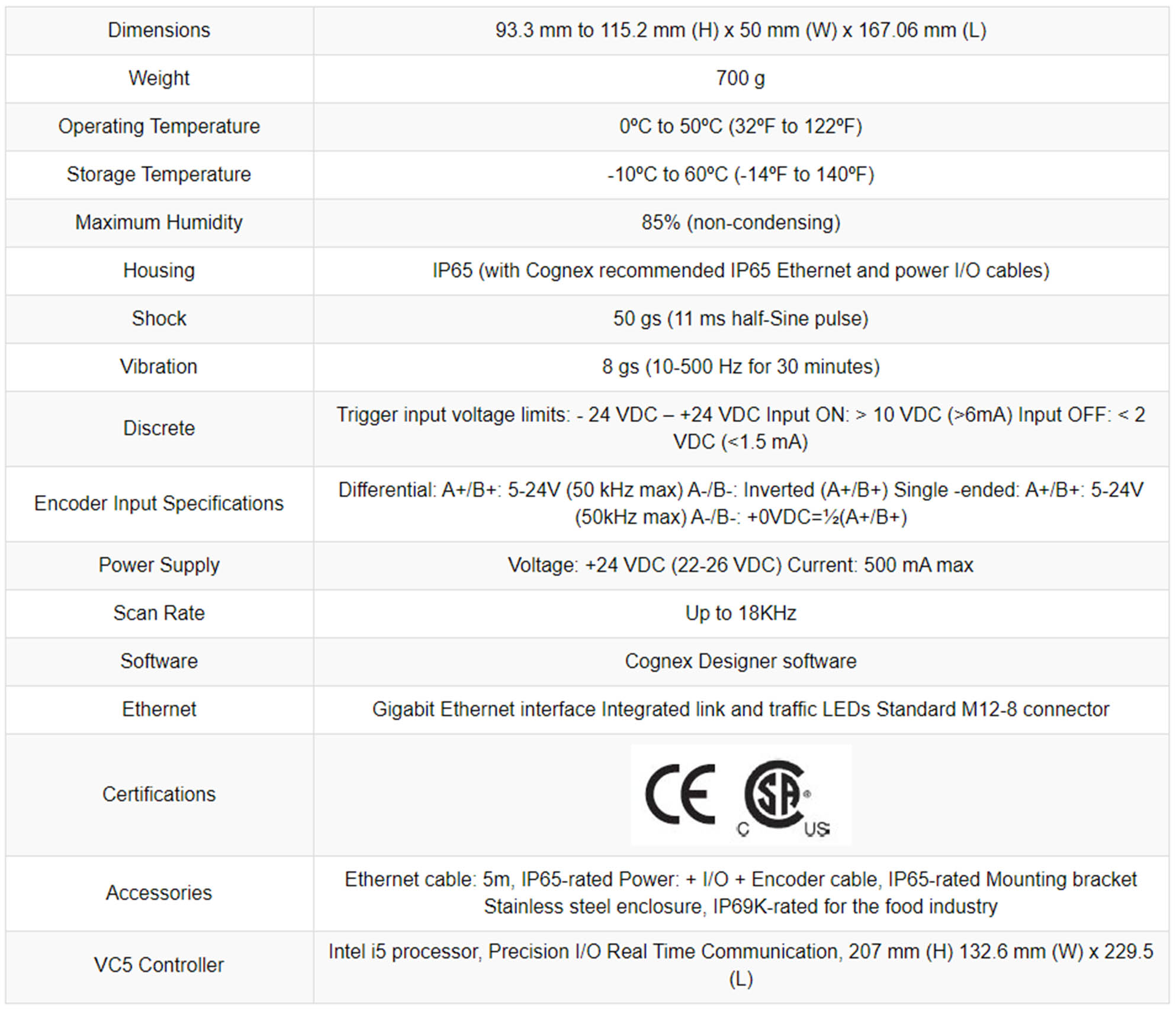

Up to 18KHz

.png)