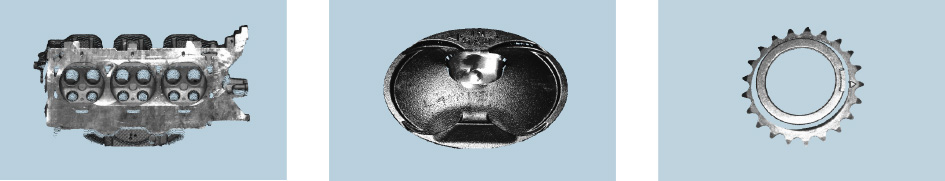

Cognex’s 3D-A5000 series is an area scan 3D camera designed to capture high-resolution 3D images. It features 3D LightBurst technology which rapidly acquires images to maximize throughput. High-resolution 3D images combined with industry-leading Cognex 3D vision tools enable reliable and accurate solutions to applications such as assembly verification, in-line measurement, and robotic guidance.

The 3D-A5000 offers a variety of fields of view and measurement ranges to accommodate applications in the automotive, consumer goods, and logistics industries. Other features and benefits include:

- Patent-pending 3D LightBurst technology enables rapid image acquisition

- More than 1.5 million 3D data points detect fine features on parts

- High Dynamic Range (HDR) mode captures scenes with high contrast

- Powerful 3D tools in VisionPro solve challenging 3D applications

- Factory-calibration delivers results in real-world units

- Rugged IP65-rated housing provides protection in harsh factory environments

Completes more 3D inspections in less time

The 3D-A5000 features 3D LightBurst technology which casts a unique blue light pattern on a part to acquire high-resolution 3D images at an unparalleled speed. It delivers a full field-of-view (FOV) 3D point cloud image as fast as 200 milliseconds, allowing higher throughput and shorter cycle times for time-critical in-line applications.

.jpg)

Delivers accurate, repeatable 3D vision inspection results

The 3D-A5000 delivers high-resolution 3D point cloud images constructed from over 1.5 million 3D data points. These high-resolution images coupled with a powerful Cognex 3D toolset in VisionPro, including PatMax 3D, allow the 3D-A5000 to solve a wide range of applications from assembly verification to in-line measurement and robotic guidance.

Performs reliably in harsh factory environments

The 3D-A5000 has a rugged IP65-rated, die cast aluminum housing that is built to last on the factory floor. The industrial design ensures consistent measurement results, even under varying temperatures.

.png)

.png)